Hydrogen

Liquefaction and

Storage Solutions

Hydrogen is a lightweight gas with a density of 0.09g/L under normal conditions. To store it efficiently, it can be compressed at very high pressures, 350 to 1000 bar, or liquefied at extremely low temperatures.

Hydrogen Liquefaction and Storage

Liquid hydrogen takes up only 1/700 times the space of its gaseous form. Because it has an extremely low boiling point of about -253°C, it can be reduced to that temperature and liqufied using special equipment and a multi-step process.

In simple terms, the hydrogen liquefaction process involves; compressing the gas, pre-cooling it through heat exchangers, cooling it a second time through expansion (Joule-Thomson effect), and finally cooling it further through cryogenic cooling. The equipment used includes compressors, heat exchangers, cryogenic coolers, and cryogenic storage tanks.

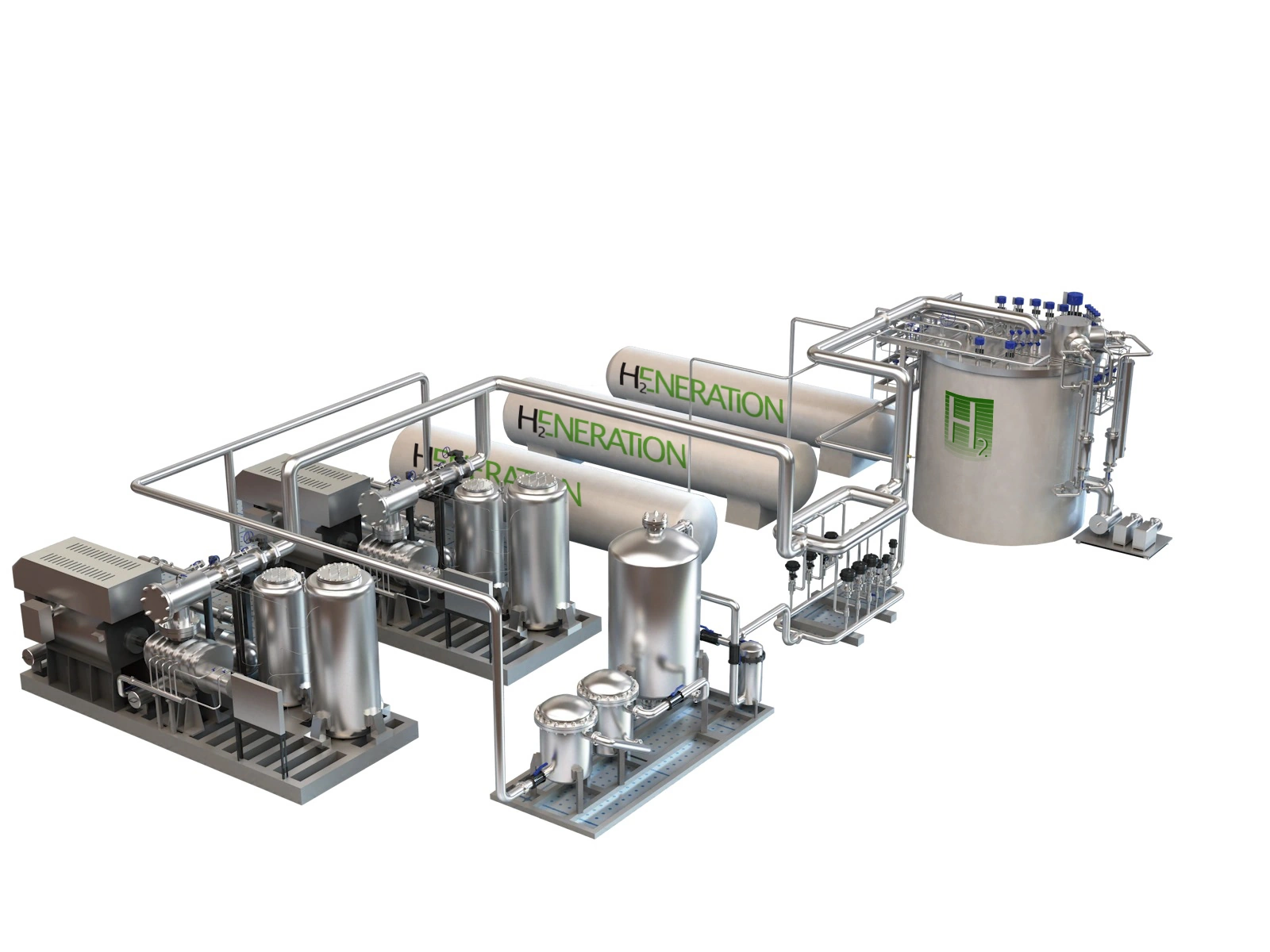

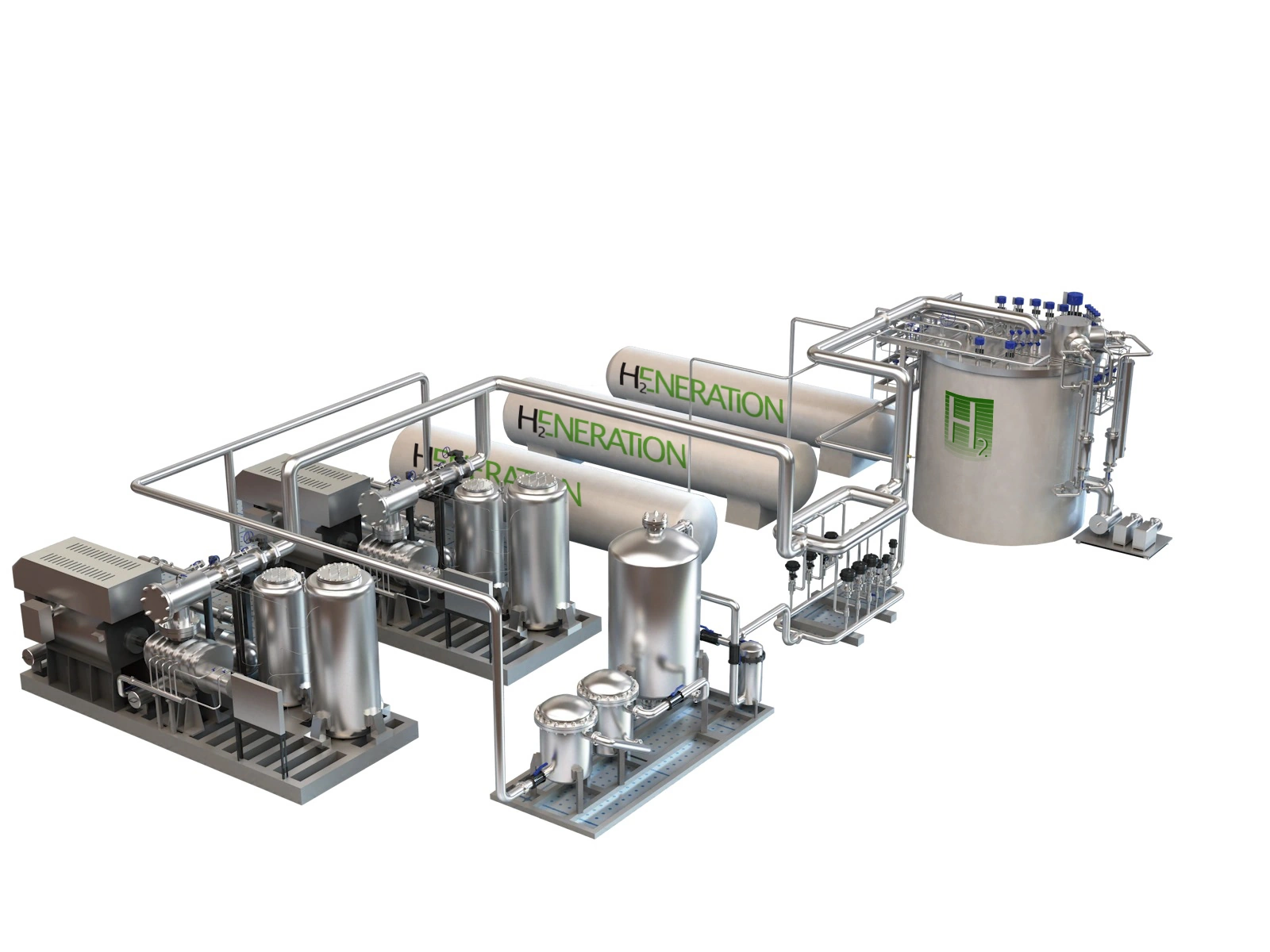

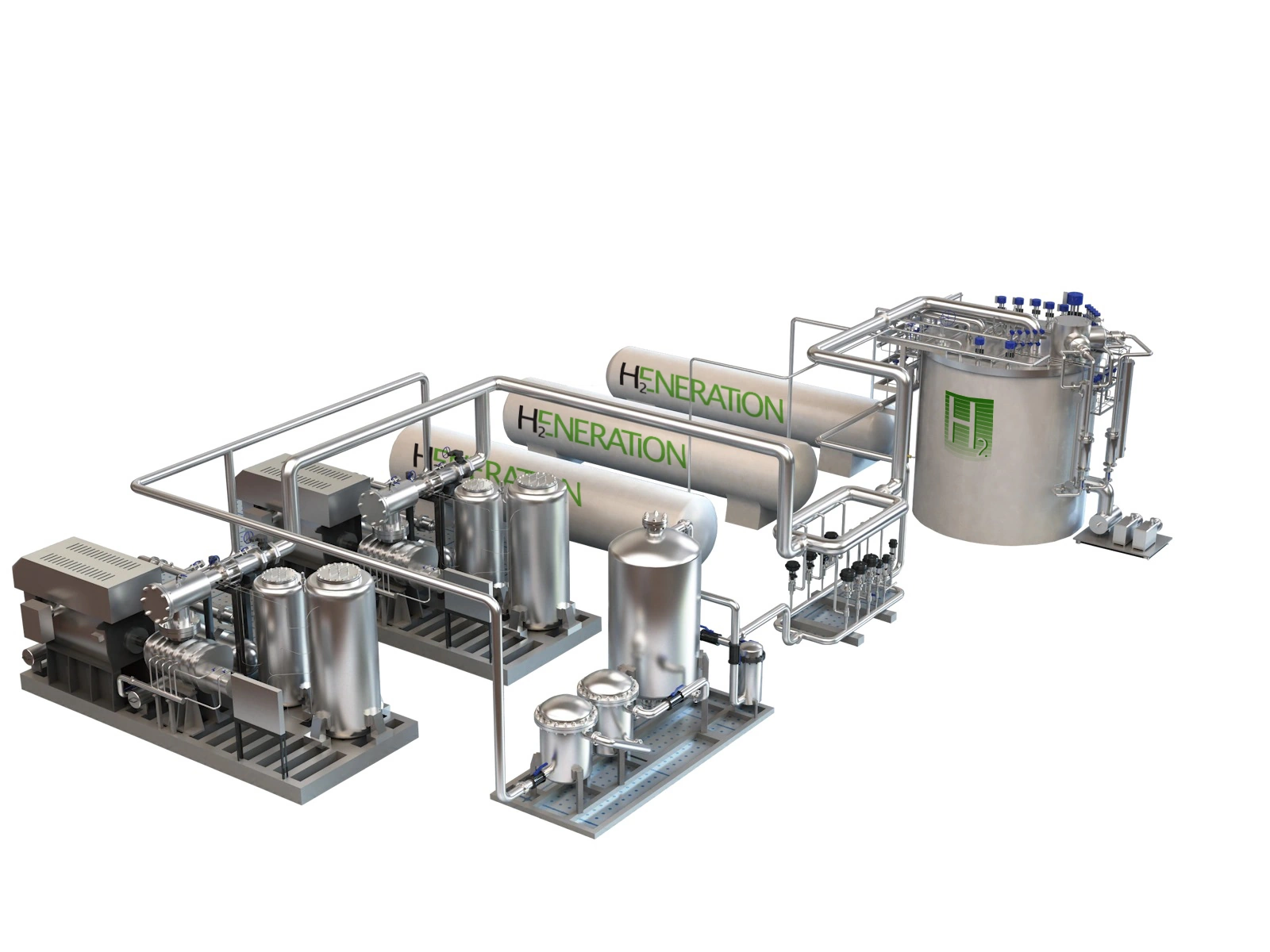

Liquefaction Systems

Compressor Unit

LIN LIH Tanks

Cold Box

Liquefaction Systems

- H2 liquefaction system process package: 0.5 t/d, 1.5 t/d, 5 t/d, 10 t/d, and 30 t/d

- Turbine expander

- Measurement and control system

- Liquid hydrogen quality monitoring

LH2 Technology

General Description

Working Principle

Applications

Hydrogen Storage

Hydrogen Storage Core Technologies

- Development of High-Pressure Liquid Hydrogen Containers (Up to 35MPa)

- Research on Liquid Hydrogen Densification Technology

- Space-Saving Non-Destructive Storage Technology

- Cryogenic Propellant On-Orbit Management Technology